As someone with experience in dealing with deep well water systems, I understand the challenges that come with hard water. Hard water, characterized by high mineral content, can wreak havoc on your plumbing, appliances, and even your well pump. In this guide, I’ll walk you through how deep well submersible pumps are designed to handle hard water effectively, ensuring you have a reliable water supply whether you’re a farmer, homeowner, restaurant owner, or part of a municipal system.

Understanding Hard Water and Its Challenges

Before diving into how deep well submersible pumps work, it’s essential to understand what hard water is. Hard water contains high levels of calcium, magnesium, and other minerals. These minerals can build up over time, leading to scale deposits that can clog pipes, reduce water flow, and damage equipment.

Why Hard Water is a Concern for Well Systems

For those using deep well water, hard water can pose several problems:

- Scale Buildup: Minerals from hard water can accumulate inside your pipes, reducing their efficiency and potentially leading to blockages.

- Pump Efficiency: Scale can also form on the surfaces of your deep well pump, affecting its performance and lifespan.

- Water Quality: Hard water can leave stains on fixtures and make soap less effective, leading to increased cleaning time and costs.

Given these challenges, it’s crucial to have a well pump system that can handle hard water effectively.

How Deep Well Submersible Pumps Combat Hard Water

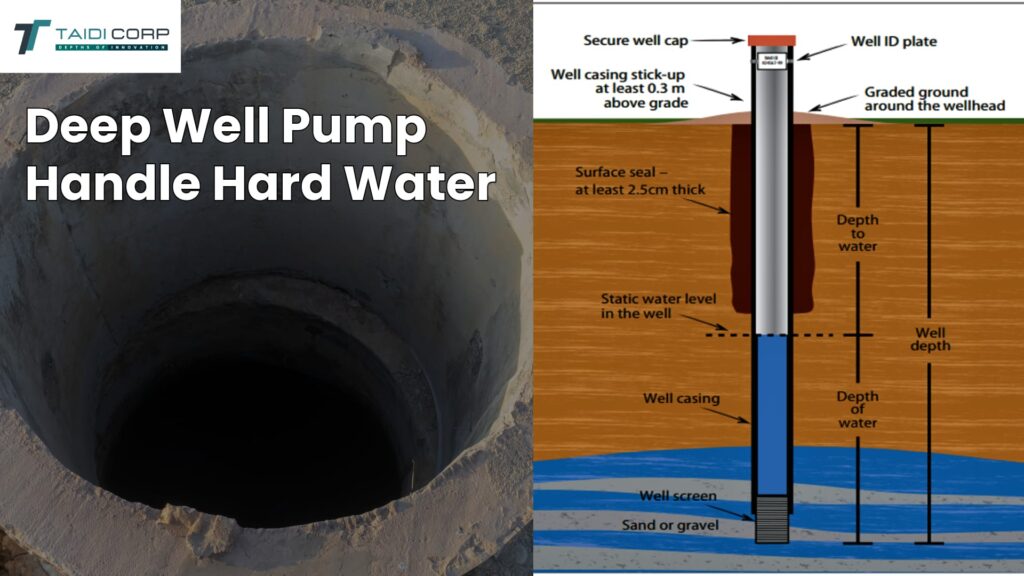

Deep well submersible pumps are engineered to operate underwater at depths where the water is often colder and more mineral-rich. Here’s how they manage to withstand the challenges posed by hard water:

1. Material Selection

One of the most critical aspects of a deep well pump is the material used in its construction. Pumps designed for hard water conditions often use stainless steel or other corrosion-resistant materials for critical components such as the impellers, diffusers, and casings. Stainless steel not only resists corrosion but also prevents scale buildup, ensuring that the pump operates efficiently for a longer time.

2. Sealing Mechanisms

Deep well submersible pumps are equipped with advanced sealing mechanisms that prevent water from entering the motor housing. These seals are vital because they protect the motor from the corrosive effects of hard water minerals. In addition, some pumps use ceramic or carbon mechanical seals, which are highly resistant to the wear and tear caused by abrasive minerals in hard water.

3. Self-Cleaning Features

Some modern deep well pumps come with self-cleaning features that minimize the impact of hard water. These pumps are designed with impellers that are less likely to accumulate scale. Additionally, some models use vibration or special coatings on the internal components to reduce mineral buildup.

4. Regular Maintenance and Monitoring

While deep well submersible pumps are robust, regular maintenance is essential to keep them functioning optimally in hard water conditions. I recommend scheduling routine inspections to check for any signs of scale buildup or wear and tear on the seals. In some cases, installing a water softening system or a filter at the wellhead can help reduce the mineral content before it reaches the pump.

For more detailed maintenance tips and best practices, I suggest reading this expert guide on maximizing the performance of deep well submersible pumps.

Selecting the Right Pump for Hard Water Conditions

When choosing a deep well pump for hard water, consider the following factors:

- Material Quality: Opt for pumps with stainless steel or other corrosion-resistant materials.

- Pump Capacity: Ensure the pump has the right capacity for your well depth and water needs.

- Self-Cleaning Features: Look for pumps that include features designed to minimize scale buildup.

Conclusion

Deep well submersible pumps are essential for managing deep well water, especially in hard water conditions. By selecting the right pump and maintaining it properly, you can ensure a reliable and efficient water supply for your home, farm, restaurant, or municipality. Remember, understanding the specific challenges of hard water and addressing them with the right equipment and practices will save you time, money, and headaches in the long run.

If you’re interested in learning more about optimizing water usage, don’t forget to check out this comprehensive guide.